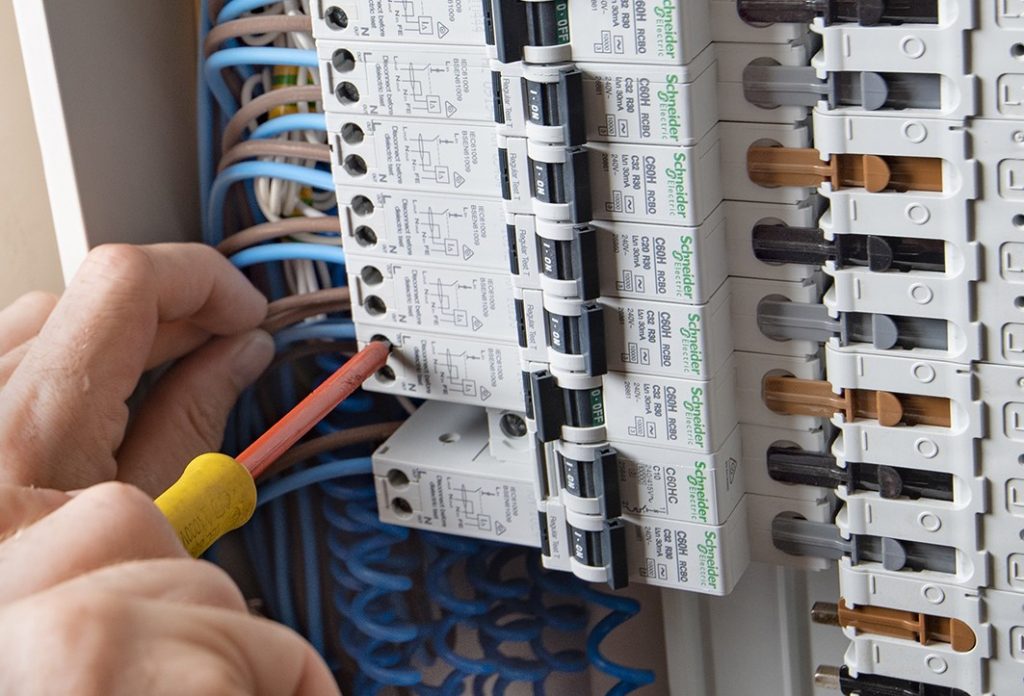

Fixed Wire Testing is the process of assessing the electrical installation and circuits which conduct electricity around the building for power and lighting. In a large site this might mean testing hundreds or even thousands of circuits – so do you need to test them all or can you just test sample?

It may initially appear that testing just a sample of circuits could be a great idea; it will naturally require less engineer time, will therefore cost less and result in fewer circuits being switched off therefore minimising the impact on the business.

However – there are two very good reasons that sampling is fraught with issues and ill-advised;

1. Periodic Testing Helps Monitor Degradation

Although the purpose of periodic inspection and testing is to ensure that an electrical installation is safe to use, it provides additional benefits; it can identify possible upcoming equipment failures that could significantly interrupt production enabling preventative maintenance to be employed as well as provide insight into the rate of degradation, which in turns helps to plan both the maintenance schedule and budget for replacements or upgrades.

Guidance Notes 3 (GN3) for the 18th Edition (Section 1.6) states that “Records of all checks, inspections and test, including test results should be kept throughout the working life of the installation. This will enable deterioration to be identified and can also be used as a management tool to ensure that maintenance checks are being carried out.”

If only a sample of the circuits are tested, it will not be possible to measure degradation over time.

2. All Circuits Need to Be Tested

In order to be sure that an installation is safe to use, the entire installation will need to be assessed.

Poor sampling creates several challenges in this regard.

For example, suppose a contractor offers to check 10% of the circuits on each distribution board. If there are 30 circuits on a DB, only 3 will be tested and it is likely that these 3 circuits will be the ones which are the easiest to identify and access.

On the next occasion, another engineer may choose the same 3 circuits for the same reasons which would enable degradation to be monitored but 90% of the circuits will remain untested.

Or if the engineer checks a different 3 circuits, there will still be a majority of circuits (80%) which remain untested which would not be a suitable basis on which to issue a satisfactory EICR.

In addition, there will be no opportunity to measure degradation over time so the quality of the inspection and testing is greatly compromised.

An Alternative Option

The 18th Edition GN3 Section 3.8.4 states that the recommended sample is 100% for the reasons outlined above – and for most companies this is the most reliable and straightforward approach.

However, for very large premises where 100% testing may not be practical, there is way to balance practicality with compliance whereby the entire site is tested within the recommended frequency (usually 3 or 5 years), but only a proportion is completed at any one time.

For example, in a large commercial office space which requires complete periodic inspection and testing every 5 years, it is possible to test a different 20% of the site every year. Of course, this needs to be carefully planned in advance to ensure that each 20% is clearly defined so that 100% of the installation is tested within the 5-year interval. In a five level multi-storey building a simple option would be to complete testing on a different level each year.

If you are interested in moving from 100% testing to 20% (for 5-year testing intervals) or 33% (for 3-year intervals) Intersafe can help manage this transition to ensure that you remain fully compliant at all times whilst spreading the cost and minimising disruption.

Looking to reliable partners to help change your testing schedule? Contact Intersafe